Automation

Automation technology is defined as the usage of set technologies and automatic control devices, resulting into an automated operation and control of industrial processes. This is achieved without significant human intervention and yields much superior performance than via manual controls.

Automation devices include PLCs, PCs, PACs, etc…, which interconnect via various industrial communication systems.

Our automation systems provide you with a futuristic answer to increasingly exacting plant and machinery requirements. Engineered to meet the needs of all industry sectors in a virtually limitless range of tasks, the superiority of our systems provides peak efficiency, extensive flexibility and high cost effectiveness in every application.

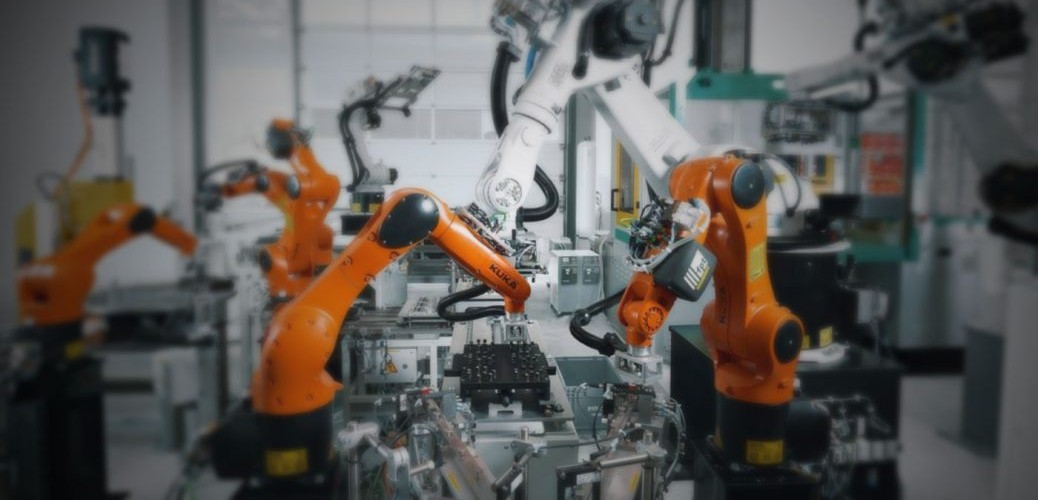

We use KUKA Robotics, a specialist in the field of robotics and automation technology and one of the leading manufacturers of industrial robots. With its wide selection of robots, KUKA covers virtually all payload ranges and robot types, and sets standards in the field of human-robot collaboration (HRC).

Food Processing

Food processing is a transformation of cooked ingredients. Food processing combines raw food ingredients to produce marketable food products that can be easily prepared and served by, and to, the consumer.

Food processing typically involves activities such as mincing and macerating, liquefaction, emulsification, cooking (such as boiling, broiling, frying, or grilling), pickling, pasteurization, dicing, slicing, freezing or drying, as well as methods of preservation, canning and other packaging…. Each process requires expertise and highly specialized machinery which are selected according to the final products required and the necessary production capacity.

Main benefits of food processing include toxin removal and long life preservation making many kinds of foods safe to consume by de-activating spoilage and pathogenic micro-organisms, thus easing marketing and distribution tasks, and increasing food consistency.

The main treated products are Fruits, Vegetables, Fish and other sea food, Meat and Dairy.

Our equipment covers processes starting from primary and secondary treatments, straight through to packaging and end of line processing.

We work with selected suppliers of quality, new and used, food processing and packaging machinery, from leading manufacturers around the globe.

Ophthalmics

Ophtalmics means “pertaining to the eye”.

We provide a broad range of machinery and process technology for ophthalmic optics, such as:

- Optics processing centers for grinding, polishing and centering/edging

- Correction polishing machines for achieving the highest possible quality

- Measuring technology, as well as alignment and joining technologies.

We supply, distribute, install and service the equipment, as well as deal in software and supplies used in ophthalmic diagnostics, surfacing prescriptions, and in-house machining and finishing lenses to fit patient frames.

OptoTech, with headquarters located in Germany, is a long-term innovator in the field of ophthalmics and a leading provider of computer integrated optical lens processing systems and ophthalmic equipment.The company has represented innovation and technological advancement in optical manufacturing equipment since 1985.

Packaging & Labeling

Packaging is the science, art and technology of enclosing or protecting products meant for distribution, storage, sale, and usage. Packaging also refers to the process of designing, evaluating and producing packages.

The packaging industry covers almost all industrial sectors, since it normally consists of the final stage in any manufacturing plant.

Labeling is any visual, written, electronic, or graphic communication, either present on the package itself, or on a separate but associated medium.

The packaging & labeling equipment that we deal with can process different materials such as carton, plastic, metals…using different and adequate technologies.

We can supply equipment and solutions for vacuum and non-vacuum packaging with high speed.

We work with our customers to deliver a “total package” that is suitable, sustainable and cost efficient, and that meets the consumer preferences of any marketplace.

Pet Food Industry

Pet food is plant or animal material intended for consumption by pets. The industry itself is a fast growing one, even at times outpacing the packaged food industry.

Typically sold in pet stores and supermarkets, it is usually specific to the type of animal, such as dog food or cat food. Meats used for pets are a byproduct of the human food industry, and are not regarded as “human grade”.

Our team will make their knowhow of complete systems towards the production of baked pet food available to you. Over 20 years of experience have given us unparalleled practical experience in technologies to supply high quality machinery, install it and provide the needed after sales service for many pet food lines.

Plastics & Rubber

Plastic is material consisting of any of a wide range of synthetic or semi-synthetic organic compounds that are malleable and so can be molded into solid objects.

Due to their low cost, ease of manufacture, versatility, and imperviousness to water, plastics are used in a multitude of products of different scale.

Plastic and rubber processing machinery and their related molds are used to produce items such as plastics bags, bottles, plastic pipes and foams, rubber hoses, caps, etc.

A multitude of processing methodologies are used and available through specialized machinery and equipment.

The equipment we handle is always designed to a very high standard ensuring durability, low maintenance and cost-effectiveness.

Quality Control & Testing

Quality Control and Testing, accompanied by robust Inspection processes, are critical in the world of manufacturing.

QC departments and production engineers can reduce iterations/tuning loops, quickly identify rejects, and reduce defective materials, simply by deriving the proper corrective actions without the real need to slow down production or affect productivity levels.

High accuracy, high precision equipment and rigid scanning and inspection analysis are often needed.

At Disctech, we can combine our vast practical experience in running several factories and equipment, to the benefit of handling such high precision equipment in camera detection, laser detection and X-Ray technologies for the analysis and testing of materials.

We are equally experienced in “weathering and environmental testing equipment” aimed at assessing the rigidity and resistance of products to their prevailing environmental conditions.

We are suppliers and installers of quality control and testing equipment from the likes of:

- YXLON International

A German specialized and worldwide leading manufacturer, designer and supplier of

- Industrial X-ray inspection systems and

- Industrial Computed Tomography (CT) systems for non-destructive testing of materials (NDT)

- Giant Force Instrument Enterprise Co., Ltd.,

A Taiwanese professional manufacturer of temperature and humidity related environmental equipment.

The products of Giant Force include: Programmable Temperature & Humidity Chambers, Thermal Shock Testers, Walk-In Environmental Test Rooms, LCM (LCD) Aging Chambers, Salt Spray Testers, Aging Ovens, Temp./ Humidity &Vibration Combined Test Chambers, Steam Aging Testers…etc.

- Atlas Material Testing Technology GmbH

A German and global leader in weathering testing technology and equipment.

ATLAS provides weathering testing instruments and services. The company offers products for various applications, including weathering testing, lightfastness testing, emission tests, physical assembly testing, solar heat load tests, high speed lighting, lighting for high-speed photography/video, UV screening, solar environmental testing, corrosion testing, flammability testing, and photoaging testing.

Recycling & Waste Management

Recycling is the process of converting waste materials into new materials and objects. It is an alternative to “conventional” waste disposal. Recycling saves material and helps lower greenhouse gas emissions.

Recycling can prevent the waste of potentially useful materials and reduce the consumption of fresh raw materials, thereby reducing: energy usage, air pollution and water pollution.

Recycling is a key component of modern waste reduction and is the third component of the “Reduce, Reuse, and Recycle” waste hierarchy.

The recycling and waste management industry is highly prioritized in the worldwide.

The related equipment is designed to maximize uptime and throughput.

Today’s most marketable end-products are using cutting-edge technology for solid waste processing and recycling.

We have partnered with some of the largest Recycling & Waste Management companies, in order to offer our customers the best machines and equipment for their Recycling & Waste Management needs.

Solar & Power

Photovoltaics (PV) is the conversion of light into electricity using semiconducting materials.

A typical photovoltaic system employs solar panels, each comprising of a number of solar cells which generate electrical power. PV installations may be ground-mounted, rooftop mounted or wall mounted. The mount may be fixed or use a solar tracker to follow the sun across the sky.

Solar PV has specific advantages as an energy source: once installed, its operation generates no pollution and no greenhouse gas emissions, it shows simple scalability with respect to power needs, and silicon, the raw material, is largely availabe in the Earth’s crust.

Solar energy is one of the most important sources of power generation via renewable energy.

We have been partnering with some of the top companies in Solar & Renewable Energy worldwide for over a decade.

We have been supplying crystalline cell manufacturing lines, thin film module lines, Photovoltaic crystalline cells turnkey lines, together with standard and back contact module lines, all through high quality machines, by partnering with:

1- SINGULUS TECHNOLOGIES

German manufacturer of photovoltaic, semiconductor, optical disc and consumer goods production lines.

SINGULUS TECHNOLOGIES develops and builds machines for economic and resource-efficient production processes with core competencies in vacuum thin-film technologies, wet-chemical processes, surface technologies, and thermal processing technologies.

2- FORMULA E S.R.L.

Italian company of talented people who have thorough experience and heritage in solar industry, automation, automated optical inspection, software and mechatronics for applications requiring high precision and accuracy in mass production.

The company continuously improves and develops their equipment and processes dedicated to PV modules manufacturing. They also provide a complete and broad variety and platform of innovative solutions solving requirements from laboratory to mass production, and enabling quite different technology roadmaps in the PV industry.

3- Applied Materials

Leader in materials engineering solutions used to produce virtually every new chip and advanced display in the world. Applied Materials’ expertise in modifying materials at atomic levels and on an industrial scale enables customers to transform possibilities into reality. Our innovations make possible the technology shaping the future.

Water Management

Water is an essential resource for all life on the planet. Of the entire water resource on Earth, only three percent is fresh water, and two-thirds of it is locked up in ice caps and glaciers. Of the remaining one percent, a fifth is in remote, inaccessible areas and much seasonal rainfall in monsoonal deluges and floods cannot easily be used.

Based on such facts, it is evident that Water Management is a topic of enormous importance.

Water management equipment are used in municipal wastewater treatment plants, as well as in many areas of industry such as pharmaceutical, chemicals, food processing, ophthalmic, etc…

The equipment’s aim is to collect and treat the wastewater so that it can be discharged safely into the environment or recycled.

Disctech is available to cooperate on such matters within all interested industries.

Welding & Cutting

Welding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by causing fusion. This is very distinct from lower temperature metal-joining techniques such as brazing and soldering, which do not melt the base metal.

In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material resulting in a combination that is usually stronger than the base material. Pressure may also be used in conjunction with heat, or by itself, to produce a weld. Welding also requires a form of shield to protect the filler metals or melted metals from being contaminated or oxidized.

Welding joins work pieces, usually metals, by melting their edges so that they fuse together. The main process is arc welding.

Cutting is a compressive and shearing phenomenon, and occurs only when the total stress generated by the cutting implement exceeds the ultimate strength of the material of the object being cut.

Cutting is used to separate pieces of metal, wood, plastic sheets, structures and pipes. This is achieved by using any of the processes of flame, plasma or laser cutting.

These two industrial fabrication processes (welding and cutting) use high-speed & high-tech machinery to transform raw materials into machines and structures.

Leather Processing

Leather is a durable and flexible material created by tanning animal rawhides, mostly cattle hide. It can be produced at manufacturing scales ranging from cottage industry to heavy industry.

The leather manufacturing process consists of is eight steps:

Step 1 – Unhairing

Step 2 – Liming

Step 3 – Deliming and Bateing

Step 4 – Pickling

Step 5 – Tanning

Step 6 – Neutralising

Step 7 – Drying

Step 8 – Finishing

The leather manufacturing process, machinery and technologies are essential for the footwear, leather goods and tanning industries.

Machines to deliver the finest final products are designed with high precision and use leading-edge technology.